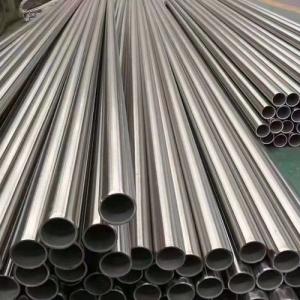

Grade 904L SMLS Stainless Steel Seamless Pipe

904L(1.4539) SEAMLESS&WELDED PIPE

904L is an austenitic stainless steel.In comparison to 316L, its molybdenum addition gives it superior resistance to localized attack (pitting and crevice corrosion) by chlorides and greater resistance reducing acids and in particular its copper addition gives it useful corrosion resistance to all concentrations of sulphuric acid. Its high alloying content also gives it greater resistance to chloride stress corrosion cracking, but it is still susceptible. Its low carbon content makes it resistant to sensitization by welding and which prevents intergranular corrosion.

STOCKING PROGRAM

- Size Range : 1/4″ ~ 36″ NPS (Larger sizes available upon request)

- Schedules : 10, 10s, 40, 40s, 80, 80s, 120, 160 (Custom wall thicknesses available upon request)

- Stainless Steel Grades : 304, 304L, 316, 316L, 316L, 317L, 321 , 347

- Special Alloys : 2205, 254SMo, Monel, Inconel

- Chrome Moly : P5, P9, P11, P22, P91

- Standards : ASTM / ASME

CHEMICAL COMPOSITION

| Element |

Cu |

Mn |

Cr |

Ni |

P |

S |

Si |

| 904L |

1.0~2.0% |

2.00% |

19.0~23.0% |

23.0~28.0% |

0.045% |

0.035% |

1.00% |

MECHANICAL PROPERTIES

| Grade |

Tensile Strength

(MPa)

Min

|

Yield Strength

0.2% proof (MPa)

Min

|

Elongation

(%in 50mm)

Min

|

Rockwell B(HRB)

|

| 904L |

490

|

220 |

36 |

70~90 |

ADVANTAGES OF WELDED

- Welded pipes are typically more cost effective than their seamless equivalents.

- Welded pipes are usually more readily available than seamless. The longer lead time required for seamless pipes can not only make timing problematic, but it also allows more time for the price of the materials to fluctuate.

- The wall thickness of welded pipes is generally more consistent than that of seamless pipes.

- The internal surface of welded tubes can be checked before manufacturing, which isn’t possible with seamless.

ADVANTAGES OF WELDED

- The main perceived advantage of seamless pipes is that they don’t have a weld seam.

- Seamless pipes provide peace of mind. Although there should be no issues with the seams of welded pipes supplied by reputable manufacturers, seamless pipes prevent any possibility of a weak seam.

- Seamless pipes have better ovality or roundness, than welded pipes.