Add to Cart

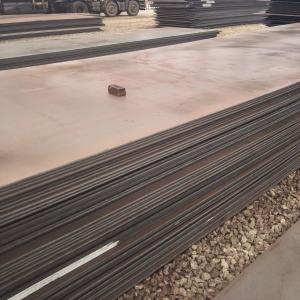

Abrasion resistant steel is used in areas where there is likely to be a high degree of abrasion or wear of the steel plate. Typical applications are in truck beds, attachments to diggers and earth movers and in processing applications in the mining industry.

GRADE

| Type | Grade | Standard |

| Abrasion Resistant Steel Plate | NM400,NM450,NM500,NM550,NM600 |

GB/T 24186-2009 |

CHEMICAL COMPOSITION

| Element | C | Si | Mn | P | S | Cr | Ni | Mo | Ti | B |

| NM400 | 0.30 | 0.70 | 1.60 | 0.025 | 0.010 | 1.00 | 0.70 | 0.5 | 0.050 | 0.0005~0.006 |

| NM450 | 0.35 | 0.70 | 1.70 | 0.025 | 0.010 | 1.10 | 0.80 | 0.55 | 0.050 | 0.0005~0.006 |

| NM500 | 0.38 | 0.70 | 1.70 | 0.020 | 0.010 | 1.20 | 1.00 | 0.65 | 0.050 | 0.0005~0.006 |

| NM550 | 0.38 | 0.70 | 1.70 | 0.020 | 0.010 | 1.20 | 1.00 | 0.70 | 0.050 | 0.0005~0.006 |

| NM600 | 0.45 | 0.70 | 1.90 | 0.020 | 0.010 | 1.50 | 1.00 | 0.80 | 0.050 | 0.0005~0.006 |

What is metal abrasion?

When materials run against one another for an extended period of time, abrasion occurs. Sometimes, abrasion is intentional, as is the case with blasting, sanding, or grinding. But, when it’s unintentional, it can lead to structural or component failure. While steel in general stands out for its resistance to abrasion, not all steels are created equal, and some steels—abrasion resistant steels—are particularly suited for applications or environments where abrasion is expected.